The Influence of Ingenious Factory Providers on Sustainable Manufacturing Practices

Innovative shop solutions play an essential role in advancing lasting manufacturing techniques. By integrating recycling innovations and energy-efficient processes, these services substantially reduce environmental influence. Factories can recover useful products, thereby lowering dependancy on virgin resources. As automation and lean manufacturing principles get traction, manufacturing performance is maximized. However, the complete level of these advancements and their effects for the future of making stay to be explored.

The Duty of Advanced Recycling Technologies in Foundries

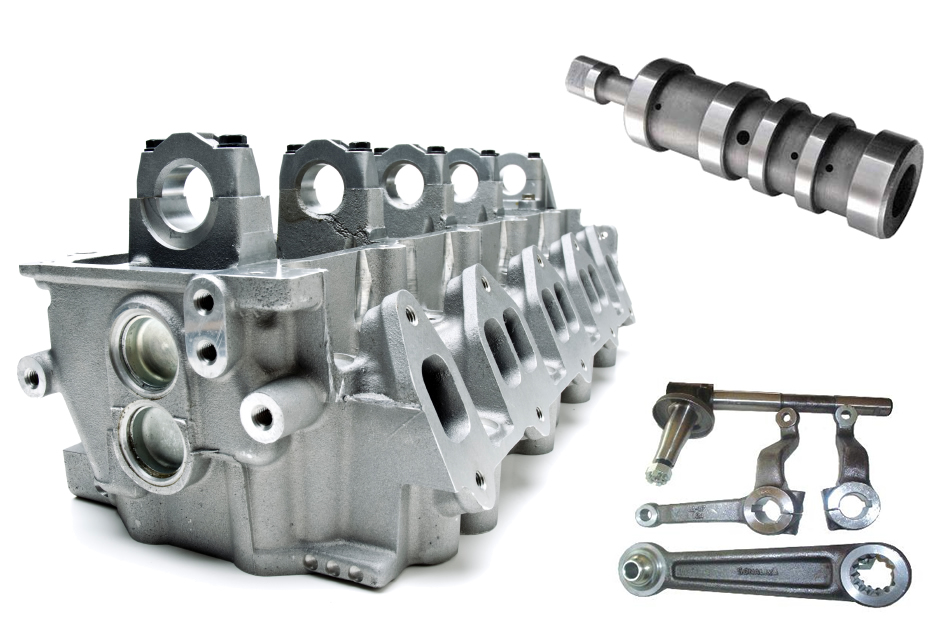

Advanced recycling innovations are changing the landscape of shops by enhancing material recuperation and decreasing waste. These innovative procedures permit shops to recover beneficial metals and materials from scrap, reducing dependence on virgin sources. By incorporating advanced sorting, shredding, and melting techniques, shops can effectively extract useful products from thrown out items, therefore advertising a circular economic climate.

Furthermore, these modern technologies sustain the production of top quality alloys and elements, ensuring that recycled materials satisfy stringent market criteria (Aluminum Foundry). Consequently, factories are not just boosting their product performance yet also decreasing the ecological effect associated with typical production methods

This change in the direction of progressed recycling not only reinforces financial viability for factories however likewise straightens with worldwide sustainability objectives. Ultimately, the consolidation of these technologies stands for a considerable advance in the mission for lasting manufacturing techniques within the shop market.

Energy Effectiveness: Minimizing Consumption in Manufacturing Processes

Energy effectiveness in producing procedures is essential for lasting operations. Methods such as process optimization techniques, eco-friendly power integration, and waste warm healing play essential duties in lessening power consumption. By concentrating on these areas, suppliers can significantly decrease their environmental influence while enhancing productivity.

Refine Optimization Techniques

A significant variety of manufacturing facilities are increasingly taking on process optimization strategies to enhance energy effectiveness and decrease consumption. These techniques include evaluating and fine-tuning manufacturing workflows, determining traffic jams, and carrying out automation to simplify procedures. By leveraging data analytics, manufacturers can keep an eye on energy usage in real-time, allowing proactive changes to minimize waste. Techniques such as Lean Production and Six Sigma concentrate on getting rid of inefficiencies and enhancing resource allotment. Additionally, progressed innovations like Internet of Things (IoT) sensors give insights right into devices performance, promoting predictive maintenance that protects against power loss. Generally, these procedure optimization techniques not just add to decreased energy consumption yet likewise promote a culture of continual improvement within producing atmospheres, straightening operational methods with sustainability objectives.

Renewable Power Integration

Lots of production facilities are progressively integrating renewable resource resources to improve general energy performance and minimize dependence on conventional power grids. This modification consists of the adoption of solar, wind, and biomass energy, which can considerably lower and decrease operational costs carbon footprints. By using these sustainable power sources, manufacturers not just reduce their environmental impact yet also enhance power durability. In addition, incorporating renewable resource systems frequently entails advanced modern technologies such as energy storage space and smart grid options, which maximize power use and promote real-time surveillance. This assimilation supports producers in achieving governing compliance and conference sustainability goals while promoting advancement in manufacturing processes. Eventually, renewable resource integration stands for a critical change towards even more sustainable manufacturing techniques and lasting practicality.

Waste Warmth Recovery

Incorporating sustainable power sources sets the stage for more advancements in energy effectiveness, especially through the implementation of waste warm healing systems. These systems catch excess thermal energy generated throughout making processes, which would certainly or else be lost to the environment. By repurposing this heat, factories can considerably lower their energy intake, lower functional costs, and minimize their carbon footprint. The recuperated heat can be made use of for different applications, such as heating, power generation, or preheating basic materials. Consequently, waste warmth recovery not only enhances energy efficiency but also adds to a sustainable manufacturing design. Innovative foundry solutions that prioritize this innovation are leading the way for an environmentally liable commercial landscape, lining up productivity with environmental stewardship.

Making Use Of Eco-Friendly Materials in Foundry Operations

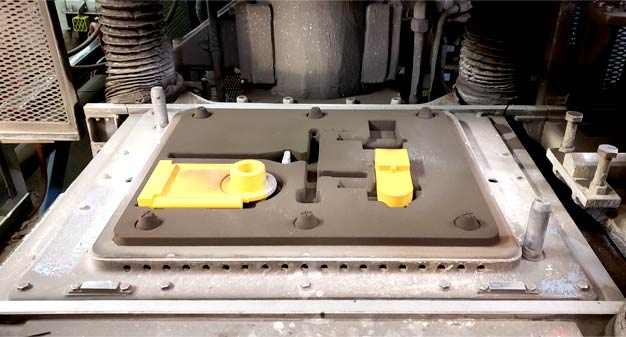

As the need for sustainable manufacturing practices expands, factories are increasingly transforming to environment-friendly products to improve their operations. By integrating sustainable options, such as recycled steels and bio-based binders, foundries can significantly minimize their environmental footprint. These materials usually call for less power for processing and can lessen damaging emissions during production.

The adoption of environmentally friendly products not just straightens with regulatory standards but also meets customer preferences for greener items. Shops are checking out ingenious alternatives, such as using natural additives that improve mold and mildew top quality while continuing to be non-toxic.

The shift to sustainable products cultivates a circular economic situation by promoting source reuse and reducing waste. Furthermore, this change can enhance the total effectiveness of shop operations, as green materials frequently show remarkable buildings, resulting in enhanced item efficiency - Aluminum Casting Company. Inevitably, the use of environment-friendly materials stands for an important action toward lasting production in the foundry industry

Technologies in Waste Administration and Decrease Techniques

The change in the direction of green products in factory procedures leads the way for innovations in waste management and reduction techniques. Cutting-edge foundry solutions are increasingly taking on approaches that reduce waste generation and promote recycling. Techniques such as closed-loop systems enable the reuse of products, greatly reducing the volume of waste generated during manufacturing procedures. In addition, developments in filtering and separation technologies allow the reliable recovery of valuable spin-offs, which can be reintegrated right into the manufacturing cycle.

In addition, the execution of real-time monitoring systems offers data-driven insights right into waste generation patterns, helping with informed decision-making to optimize source usage. Foundries are also exploring his comment is here biowaste solutions, transforming organic waste right into energy or usable products, further promoting sustainability. These advancements not only contribute to a circular economic climate however also boost the overall ecological efficiency of foundry operations, emphasizing the sector's commitment to lowering its environmental footprint.

The Effect of Automation on Lasting Manufacturing

While numerous sectors objective for sustainability, automation arises as a necessary element in boosting lasting manufacturing practices within shops. By integrating automated systems, shops can accomplish higher performance, reduce waste, and lower power consumption. Automated procedures enable specific control over manufacturing specifications, decreasing defects and rework, which in turn preserves sources.

In addition, automation promotes the monitoring of ecological influences, enabling real-time adjustments that line up with sustainability goals. aluminum casting. Advanced robotics and expert system can maximize material usage, causing significant reductions in scrap and exhausts

Furthermore, automated innovations promote more secure workplace by taking care of hazardous jobs, thus improving worker health while ensuring compliance with ecological guidelines. Generally, the adoption of automation within factories not just improves operations however likewise plays an essential duty ahead of time sustainable manufacturing techniques, adding to a much more accountable industrial landscape.

Instance Researches: Effective Execution of Lasting Foundry Practices

Successful implementation of sustainable methods in shops can be shown through different study that highlight measurable end results and innovative approaches. One remarkable example is a mid-sized factory that adopted a closed-loop water recycling system, reducing water intake by 40% and reducing wastewater generation. Additionally, this center transformed to utilizing green mold materials, which not only enhanced item high quality however also enhanced worker about his safety.

One more significant instance entailed a large shop incorporating sustainable power resources, such as solar panels, which balance out 30% of its power needs. This initiative not just decreased operational prices but additionally added to a substantial reduction in carbon emissions.

Lastly, a factory that applied lean manufacturing methods reported a 25% increase in effectiveness, leading to less worldly waste and maximized manufacturing processes. These situations jointly emphasize the tangible benefits and sustainability developments possible via innovative foundry techniques.

Often Asked Questions

Exactly How Do Ingenious Shop Services Add To Total Sustainability Goals?

Innovative foundry services enhance overall sustainability objectives by enhancing resource usage, decreasing waste, and improving power efficiency. These advancements add to reduce carbon footprints and advertise eco responsible methods within the production field, sustaining more comprehensive sustainability initiatives.

What Are the Economic Benefits of Taking On Sustainable Foundry Practices?

Taking on sustainable factory practices can lower operational expenses, boost resource performance, and improve competition. In addition, these methods can draw in eco-conscious customers and capitalists, ultimately bring about enhanced productivity and lasting economic practicality for services.

How Can Little Foundries Implement Sustainable Technologies Effectively?

Small foundries can apply lasting developments efficiently by adopting energy-efficient modern technologies, enhancing resource usage, training team on lasting practices, teaming up with vendors for environmentally friendly products, and taking part in continual enhancement procedures to minimize waste and emissions.

What Certifications Exist for Lasting Shop Workflow?

How Do Consumer Preferences Impact Sustainable Production in Foundries?

Customer choices substantially affect sustainable production in shops by driving demand for green items. As consumers focus on sustainability, foundries adapt their practices, including greener modern technologies and products to meet market expectations basics and boost their competitive advantage.

By repurposing this warmth, foundries can significantly decrease their power intake, lower operational prices, and reduce their carbon impact. Factories are also discovering biowaste remedies, transforming organic waste into energy or usable products, even more advertising sustainability. By integrating automated systems, factories can attain higher effectiveness, minimize waste, and reduced energy intake. Another significant case entailed a large factory integrating sustainable power sources, such as solar panels, which offset 30% of its energy requires. Cutting-edge factory solutions improve general sustainability objectives by maximizing resource usage, lowering waste, and boosting power effectiveness.